Digital twins, a revolutionary concept, are virtual representations of physical assets, systems, or processes. They offer a powerful tool for understanding, optimizing, and predicting the behavior of their real-world counterparts, enabling data-driven decisions and transformative innovations.

Table of Contents

From manufacturing to healthcare, transportation to urban planning, digital twins are being implemented across industries, unlocking new possibilities for efficiency, cost reduction, and improved performance. These virtual replicas capture real-time data, integrate with sensors and simulations, and provide a dynamic platform for analyzing and visualizing complex systems.

Definition and Concepts

A digital twin is a virtual representation of a physical asset, process, or system that mirrors its real-world counterpart in real-time. It leverages data from sensors, simulations, and other sources to create a dynamic and comprehensive digital replica. The digital twin serves as a bridge between the physical and digital worlds, enabling a deeper understanding, optimization, and control of the physical asset.

Relationship between a Digital Twin and its Physical Counterpart

The relationship between a digital twin and its physical counterpart is bidirectional and dynamic. Data from the physical asset is continuously collected and fed into the digital twin, updating its state and behavior. Conversely, the digital twin can be used to simulate changes and scenarios, providing insights that can be applied to the physical asset. This continuous feedback loop enables a closed-loop system where the digital twin informs and influences the physical asset, while the physical asset provides real-time data to the digital twin.

Types of Digital Twins

Digital twins can be categorized based on their purpose and the level of complexity they represent.

- Asset-Level Digital Twins: These twins focus on a single physical asset, such as a machine, a building, or a vehicle. They are used to monitor performance, predict maintenance needs, and optimize operations. For example, a digital twin of a wind turbine can be used to analyze its performance in real-time, predict potential failures, and optimize its energy output.

- Process-Level Digital Twins: These twins represent a complete process, such as a manufacturing line or a supply chain. They are used to simulate different scenarios, optimize workflows, and identify bottlenecks. For instance, a digital twin of a manufacturing line can be used to simulate different production plans, identify potential disruptions, and optimize production efficiency.

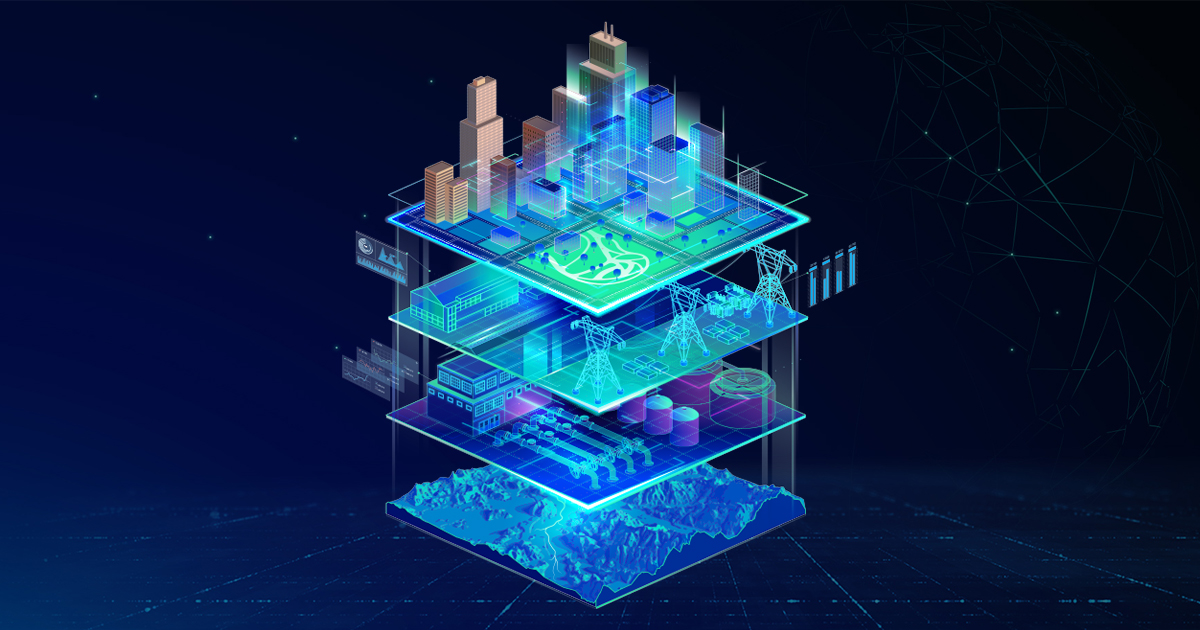

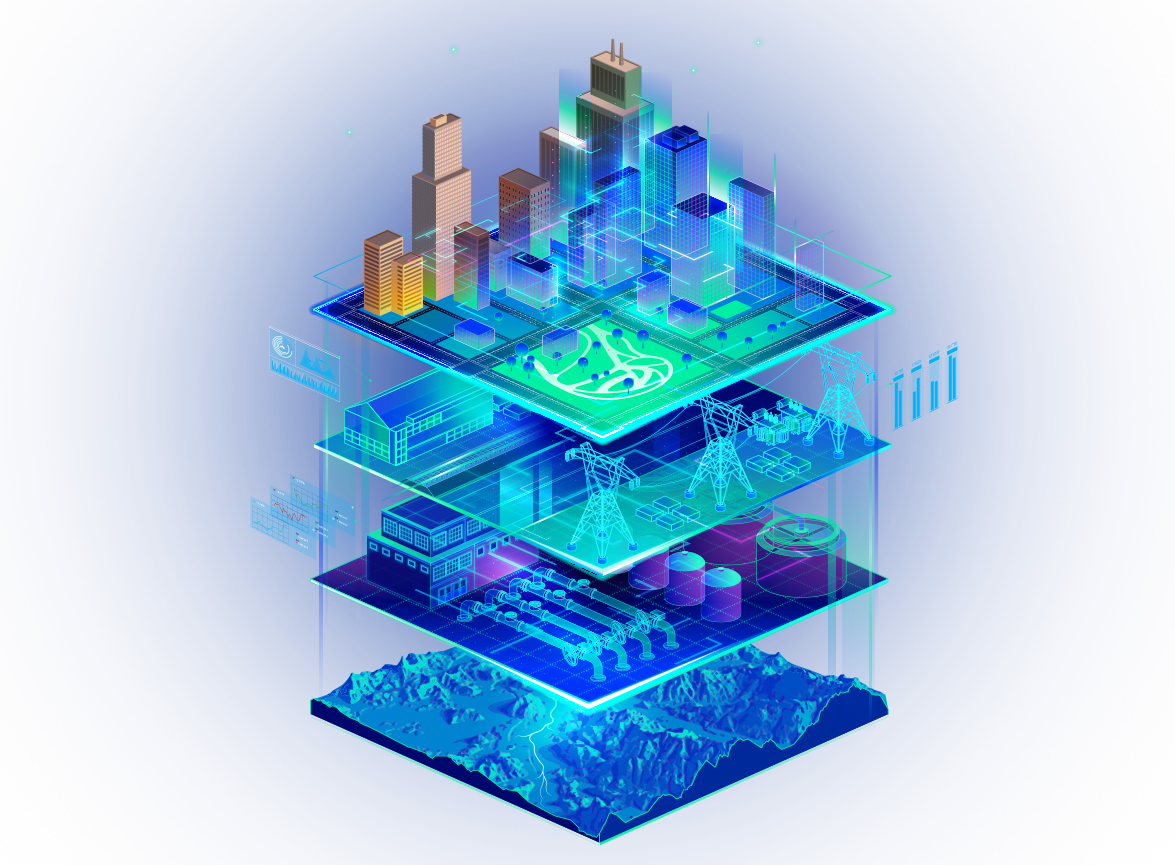

- System-Level Digital Twins: These twins represent complex systems, such as a city or a power grid. They are used to model and analyze the interactions between different components, predict system behavior, and optimize performance. For example, a digital twin of a city can be used to simulate the impact of urban planning decisions on traffic flow, energy consumption, and environmental impact.

Benefits of Digital Twins

Digital twins offer numerous benefits across various industries.

- Improved Decision Making: By providing real-time data and insights, digital twins enable informed and data-driven decision-making. This can lead to better resource allocation, optimized operations, and reduced downtime.

- Enhanced Performance: Digital twins can be used to identify areas for improvement and optimize the performance of physical assets. This can lead to increased efficiency, reduced costs, and improved product quality.

- Predictive Maintenance: By analyzing sensor data and historical trends, digital twins can predict potential failures and schedule maintenance proactively. This can help prevent unexpected downtime and reduce maintenance costs.

- Virtual Prototyping: Digital twins can be used to test and evaluate different designs and configurations before they are implemented in the physical world. This can help reduce development time, costs, and risks.

- Real-Time Monitoring: Digital twins provide real-time monitoring of physical assets, enabling operators to track performance, identify anomalies, and respond to issues quickly.

Components of a Digital Twin

A digital twin is a virtual representation of a physical asset or process, encompassing its characteristics, behaviors, and interactions. It’s essentially a dynamic, data-driven model that mirrors the real-world counterpart, providing valuable insights for decision-making, optimization, and predictive maintenance.

The creation and maintenance of a digital twin involve a complex interplay of several key components. These components work in harmony to capture, analyze, and simulate real-world data, enabling a comprehensive and accurate representation of the physical asset.

Data Acquisition

Data acquisition is the foundation of a digital twin, as it provides the raw material for creating and maintaining the virtual representation. This involves collecting data from various sources, including sensors, actuators, cameras, and databases. The type of data collected depends on the specific asset and the desired level of detail for the digital twin.

The process of data acquisition can be categorized into two primary types:

- Real-time data acquisition: This involves capturing data continuously from sensors and actuators, providing a real-time snapshot of the asset’s state. Examples include temperature readings from a manufacturing process, vibration data from a turbine, or GPS coordinates from a vehicle.

- Historical data acquisition: This involves gathering data from past records, such as maintenance logs, production reports, or environmental data. This data provides context and historical trends that can be used to understand the asset’s behavior over time.

Data Processing and Analysis

Once data is acquired, it needs to be processed and analyzed to extract meaningful insights. This involves cleaning, transforming, and aggregating the raw data into a format that can be used for modeling and simulation.

- Data cleaning: This involves removing errors, inconsistencies, and outliers from the data to ensure its accuracy and reliability.

- Data transformation: This involves converting data into a format that is suitable for analysis and modeling. For example, raw sensor data might need to be converted into meaningful units or aggregated over time.

- Data analysis: This involves applying statistical and machine learning techniques to identify patterns, trends, and anomalies in the data. This helps to understand the asset’s behavior, identify potential problems, and make informed decisions.

Modeling and Simulation

Modeling and simulation are crucial for creating a dynamic and predictive digital twin. They enable the representation of the asset’s behavior, interactions, and responses to different scenarios.

- Physical models: These models represent the asset’s physical characteristics, such as geometry, material properties, and mechanical behavior. They are used to simulate the asset’s response to external forces, loads, and environmental conditions.

- Behavioral models: These models represent the asset’s functional behavior, such as control systems, operating parameters, and performance metrics. They are used to simulate the asset’s performance under different operating conditions and scenarios.

- Simulation: This involves running the models to predict the asset’s behavior under different conditions. It allows for testing various scenarios, optimizing performance, and identifying potential risks.

Visualization and Interaction, Digital twin

Visualization and interaction are key for understanding and utilizing the digital twin. They provide a user-friendly interface for exploring the data, models, and simulations.

- Interactive dashboards: These provide a visual representation of the asset’s data, models, and simulations. They allow users to explore the data, analyze trends, and identify potential issues.

- 3D visualizations: These provide a realistic representation of the asset in its environment. They allow users to interact with the digital twin, exploring different views and perspectives.

- Augmented reality (AR) and virtual reality (VR): These technologies can be used to overlay the digital twin onto the real-world asset, providing a more immersive and interactive experience. This allows users to visualize the asset’s data and models in context.

Integration and Connectivity

A digital twin is not a standalone entity. It needs to be integrated with other systems and data sources to provide a comprehensive view of the asset and its environment.

- Data integration: This involves connecting the digital twin to various data sources, such as sensors, databases, and enterprise resource planning (ERP) systems. This allows for the exchange of data and information between the digital twin and other systems.

- API connectivity: This enables the digital twin to communicate with other applications and services. This allows for the integration of the digital twin into existing workflows and processes.

- Cloud connectivity: This enables the digital twin to leverage the power of cloud computing, providing scalability, storage, and processing capabilities.

Security and Privacy

As digital twins handle sensitive data, security and privacy are paramount. Measures need to be implemented to protect the data from unauthorized access, modification, or disclosure.

- Data encryption: This involves encrypting the data to protect it from unauthorized access.

- Access control: This involves limiting access to the data based on user roles and permissions.

- Data governance: This involves establishing policies and procedures for managing data security and privacy.

Applications of Digital Twins

Digital twins have emerged as a transformative technology, finding widespread adoption across various industries and sectors. Their ability to create virtual representations of physical assets and systems enables organizations to gain deeper insights, optimize operations, and make data-driven decisions. This section explores the diverse applications of digital twins, highlighting specific use cases and the associated benefits and challenges.

Manufacturing

Digital twins are revolutionizing the manufacturing industry by providing real-time insights into production processes, equipment performance, and product quality.

- Predictive Maintenance: Digital twins can analyze sensor data from machines to predict potential failures and schedule maintenance proactively. This reduces downtime, optimizes maintenance costs, and improves overall equipment efficiency.

- Process Optimization: By simulating different production scenarios, manufacturers can identify bottlenecks, optimize resource allocation, and enhance production efficiency. This can lead to shorter lead times, reduced waste, and increased output.

- Product Design and Development: Digital twins enable manufacturers to test and refine product designs virtually before physical prototypes are created. This accelerates the design process, reduces costs, and improves product quality.

Healthcare

Digital twins are transforming healthcare by providing personalized patient care, improving treatment outcomes, and enhancing medical research.

- Personalized Medicine: Digital twins can model individual patient physiology and response to treatments, enabling doctors to tailor therapies for optimal outcomes. This can lead to more effective treatments and fewer side effects.

- Surgical Planning and Simulation: Digital twins of patients’ anatomy allow surgeons to plan complex procedures virtually, reducing risks and improving surgical outcomes. This technology is particularly beneficial for minimally invasive surgeries and complex procedures.

- Drug Discovery and Development: Digital twins can simulate the effects of drugs on different patients, accelerating the drug discovery process and reducing the cost of clinical trials.

Transportation

Digital twins are playing a crucial role in optimizing transportation systems, enhancing safety, and improving efficiency.

- Autonomous Vehicles: Digital twins are essential for developing and testing autonomous vehicles. They allow engineers to simulate real-world driving scenarios, optimize vehicle control algorithms, and ensure safety.

- Traffic Management: Digital twins of traffic networks can analyze real-time traffic data to optimize traffic flow, reduce congestion, and improve travel times. This can lead to smoother commutes and reduced fuel consumption.

- Infrastructure Maintenance: Digital twins of bridges, roads, and other infrastructure assets can monitor their condition, predict potential failures, and schedule maintenance proactively. This ensures the safety and longevity of critical infrastructure.

Other Industries

Beyond these core industries, digital twins are finding applications in a wide range of sectors, including:

- Energy: Digital twins can optimize power generation, distribution, and consumption, leading to increased efficiency and reduced energy costs.

- Finance: Digital twins can model financial markets and economic conditions, enabling better risk management and investment decisions.

- Retail: Digital twins can optimize store layouts, inventory management, and customer experiences, leading to increased sales and customer satisfaction.

- Education: Digital twins can create immersive learning environments, personalize instruction, and enhance student engagement.

Benefits of Digital Twins

Digital twins offer a powerful approach to understanding, optimizing, and innovating across various industries. By creating a virtual representation of a physical asset or process, digital twins provide valuable insights that can lead to significant improvements in efficiency, cost reduction, and decision-making.

Improved Efficiency

Digital twins can significantly enhance efficiency by providing real-time insights into asset performance, enabling proactive maintenance and optimization.

- Predictive Maintenance: By analyzing data from sensors and other sources, digital twins can predict potential failures before they occur, allowing for timely maintenance and minimizing downtime. For example, in the aerospace industry, digital twins are used to monitor the health of aircraft engines, predicting potential issues and scheduling maintenance before they become critical, leading to significant cost savings and improved safety.

- Process Optimization: Digital twins can be used to simulate different scenarios and optimize processes, leading to increased efficiency and reduced waste. In manufacturing, digital twins can be used to simulate production lines and identify bottlenecks, optimizing production flow and minimizing downtime.

Reduced Costs

The insights gained from digital twins can lead to significant cost reductions through improved efficiency, optimized resource allocation, and reduced risk.

- Reduced Downtime: By enabling predictive maintenance, digital twins minimize downtime and reduce repair costs. In the oil and gas industry, digital twins are used to monitor the performance of offshore platforms, predicting potential issues and scheduling maintenance before they become critical, reducing downtime and minimizing production losses.

- Optimized Resource Allocation: Digital twins can help optimize resource allocation by providing insights into asset utilization and performance. In the logistics industry, digital twins can be used to simulate different delivery routes and optimize fleet management, reducing fuel consumption and transportation costs.

Enhanced Decision-Making

Digital twins provide a comprehensive and data-driven approach to decision-making, enabling better informed choices based on real-time insights.

- Scenario Planning: Digital twins can be used to simulate different scenarios and assess the potential impact of various decisions. In the energy sector, digital twins can be used to simulate different energy generation and distribution scenarios, helping to optimize grid operations and ensure reliable energy supply.

- Risk Assessment: Digital twins can be used to assess risks and identify potential problems before they occur, enabling proactive mitigation strategies. In the construction industry, digital twins can be used to simulate the construction process and identify potential safety hazards, enabling proactive measures to be taken to ensure worker safety.

Innovation and New Opportunities

Digital twins are not only about optimizing existing processes but also about driving innovation and creating new opportunities.

- Product Development: Digital twins can be used to simulate product performance and optimize design, leading to faster and more efficient product development cycles. In the automotive industry, digital twins are used to simulate vehicle performance and optimize design, reducing development time and improving vehicle efficiency.

- New Business Models: Digital twins can be used to create new business models and generate new revenue streams. In the healthcare industry, digital twins can be used to create personalized treatment plans based on patient-specific data, leading to more effective and efficient healthcare delivery.

Challenges and Limitations

While digital twins offer significant potential, their development and implementation come with challenges and limitations. These hurdles can impact the effectiveness and accuracy of digital twins, requiring careful consideration and mitigation strategies.

Data Security and Privacy

Data security and privacy are paramount concerns in digital twin development. Digital twins rely on vast amounts of data collected from various sources, including sensors, databases, and user interactions. This data often contains sensitive information, raising concerns about its protection.

- Data breaches: Unauthorized access to sensitive data can lead to significant financial losses, reputational damage, and legal consequences. For example, in 2017, Equifax, a credit reporting agency, experienced a data breach that compromised the personal information of millions of customers.

- Data misuse: Even with proper security measures, there is a risk of data misuse, such as unauthorized sharing or analysis for purposes other than intended. This can violate privacy and lead to ethical concerns.

- Data governance: Establishing clear data governance policies and procedures is crucial to ensure data security and privacy. This involves defining data ownership, access rights, and data retention policies.

Bias and Inaccuracies in Digital Twin Models

Digital twin models are trained on data, and if this data contains biases, the models may inherit and amplify these biases. This can lead to inaccurate predictions and decisions, particularly in areas like risk assessment, resource allocation, and customer segmentation.

- Data selection bias: The data used to train digital twin models may not be representative of the real-world system. This can occur due to sampling errors, incomplete data, or intentional data manipulation.

- Algorithmic bias: The algorithms used to create and train digital twin models can themselves introduce biases. For example, algorithms may favor certain groups or outcomes based on historical data that reflects existing societal biases.

- Model validation: It is essential to rigorously validate digital twin models to identify and mitigate potential biases. This involves testing the models on diverse datasets and comparing their performance to real-world outcomes.

Ethical Considerations

The development and deployment of digital twins raise ethical considerations, particularly regarding the potential for misuse, discrimination, and accountability.

- Transparency and explainability: Digital twin models can be complex and difficult to understand. This lack of transparency can make it challenging to identify and address biases or unintended consequences.

- Accountability: Establishing accountability for the actions of digital twins is crucial, especially in cases where they make decisions that have significant consequences.

- Fairness and equity: Digital twins should be designed and implemented in a way that promotes fairness and equity. This involves ensuring that they do not perpetuate or amplify existing biases.

Epilogue

The future of digital twins is bright, with advancements in artificial intelligence, machine learning, and the Internet of Things driving further innovation. As we continue to leverage the power of these virtual representations, we can expect to see transformative changes across industries, fostering a future where data-driven insights and predictive capabilities drive unprecedented efficiency and progress.

A digital twin is a virtual representation of a physical asset, allowing for simulations and analysis. These simulations can be used to optimize performance, identify potential issues, and even predict future behavior. For example, you could use a digital twin of your computer to analyze its performance and identify areas for improvement, such as by downloading a tool like CCleaner to clean up unnecessary files and optimize your system.

The insights gained from the digital twin can then be used to make informed decisions about the physical asset, leading to improved efficiency and performance.